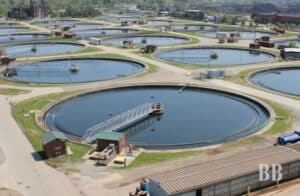

GLWA Aeration System Improvements

GLWA Detroit Wastewater Treatment Plant

Wastewater aeration is a biological treatment that uses naturally occurring microorganisms to degrade wastewater contaminants. Adding air into wastewater allows aerobic bio-degradation of the pollutant components. It is an integral part of the secondary wastewater treatment process. Aeration is the most critical component of a treatment system using the activated sludge process.

How Aeration Works

Aeration promotes microbial growth in the wastewater and those microbes feed on the organic material, forming flocs, loosely clumped masses of fine particles, that settle more readily. The settled flocs can then be separated from the processed water and recirculated to increase the rate of decomposition.

A well-designed aeration system has a direct impact on the level of wastewater treatment it achieves. An ample and evenly distributed oxygen supply in an aeration system is the key to effective wastewater treatment.

Aeration System Improvements at the Detroit Wastewater Treatment Plant

Rotor Electric of Michigan was selected by Weiss Construction to complete improvements to the aeration system at the Detroit Wastewater Treatment Plant (WWTP). The Detroit WWTP is the largest single-site WWTP in the United States and has been in service since 1940. The plant has primary capacity of 1.8 billion gallons per day (BGD) and secondary capacity of 1.82 BGD.

The goal of this project GLWA-PC-796 was to improve the system and provide necessary interconnections. The work included replacement of fabricated steel and fiberglass process piping, magnetic flow meters, gate valves, fabricated wedge gate valves and butterfly valves, sluice gates and actuators, variable frequency drives, miscellaneous architectural, structural, HVAC, electrical, and Instrumentation controls.

The completion of this project allows the WWTP to continue operating efficiently and effectively. Rotor Electric of Michigan is proud to have contributed to this vital process.

The scope of work included:

- Installation of three (3) new 2500 HP 4,160V Variable Frequency Drives (VFDs)

- Replacement of all Vibration Monitoring equipment for better preventative maintenance

- Replacement of the entire combustible gas monitoring system to improve safety

- All of this work is being done while maintaining an operating facility.