Lake Huron Water Treatment Plant

High Lift Pump Exciter Cubicle Retrofit

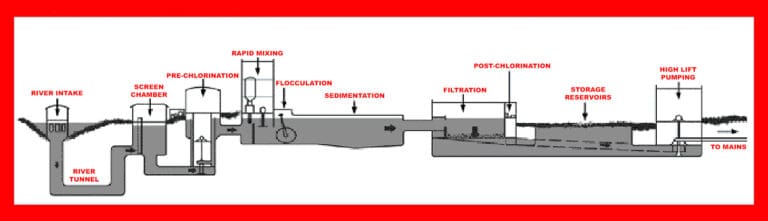

The Lake Huron Water Treatment Plant (LHWTP) supplies water to 59 wholesale customers. The facility began operation in 1973. The high service pump station houses eight (8) vertical pumping units and associated piping, valves, electrical gear, and auxiliary services. LHWTP has five GE 5500HP vertical synchronous pump motors (13.2kV).

Aging Infrastructure

After 45 years, much of the pump equipment has reached or is nearing the end of its useful operating life. In 2017, the LHWTP staff found it more challenging to maintain the aging high lift field cubicles. High-lift pumps discharge treated water into arterial mains and operate under higher pressures. Failure is a critical component that will render a high lift pump motor unusable unless upgraded to modern standards.

GLWA-DB-173 is a design/build contract awarded to Rotor Electric of Michigan, LLC, to provide upgrade solutions and implementation for a single high lift field cubicle at the LHWTP. The main issues relate to the existing DC rotating excitation system.

Project Scope

The scope of services for this project includes addressing all facility modifications required to install the new field cubicle components, including the development of system isolation plans and all aspects of putting the equipment back into service while minimizing disruption to the water supply system. Construction teams must coordinate high service water flow disruptions with GLWA Water Supply Operations staff based on seasonal and daily fluctuations in water demands from customers.

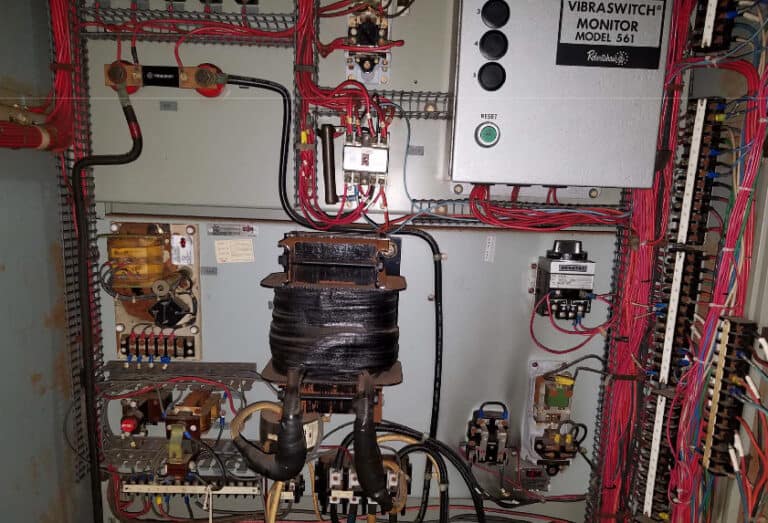

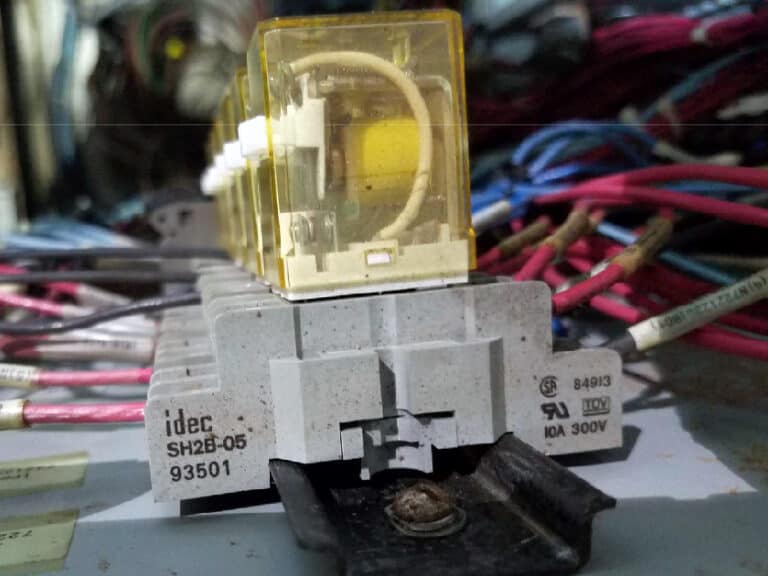

High Lift Field Cubicle Repairs

Rotor handles the professional engineering and construction services, including completion of selective demolition of a single cubicle and construction of the repairs for each designated portion of the booth. Including relays and controls, termination strips, installation of a 120V cubicle heater and thermostat to prevent further corrosion, and the addition of an automatic power factor control from the excitation system. Upon completing the first high lift field cubicle work, GLWA may expand the project to include the remaining four units.